One of the most commonly requested types of print project requests my clients have is debossed business cards. I get it! They’re beautiful. However, my clients are often a bit surprised at their cost or the options available to them when it comes to debossing. Let’s compare the differences between debossing done on letterpress machines vs. modern equipment, so you can learn more about the differences and similarities between the two types of printing and make the best decision for your next print project.

Defining Letterpress and Deboss

First, let’s take a closer look at the two terms and what they represent. Debossing is a form of relief printing, which means that it leaves a depression in the paper. Letterpress was the name given to one of the earliest forms of modern printing and was first defined as “printed text as opposed to illustrations”, and while letterpress printers can produce flat prints, they are capable of debossing as well.

In basic terms, deboss = a depression, and letterpress = a technique that can deboss.

Ultimately, the two terms are interchangeable. However, in the modern printing landscape, there are a few notable differences in the understanding of each term. Below, you’ll find a comparison between the two so you feel confident going into your next project.

Letterpress Printing

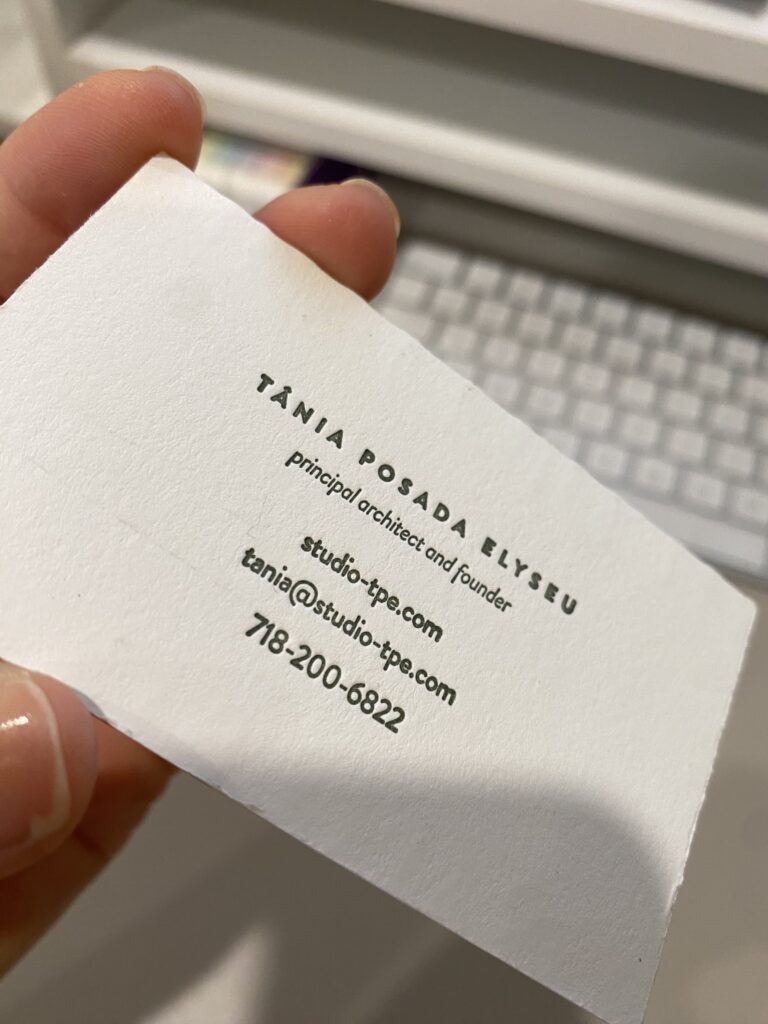

Letterpress is the oldest form of printing, with a history that traces back to Germany in the year 1440. By the 1970s, letterpress machines began to become obsolete as modern offset printing became more popular. Today, printers who offer letterpress are using antique letterpress machines. Unlike modern debossing equipment, letterpress machines yield a more artisanal look due to the use of polymer plates and, typically, a softer, uncoated paper stock.

The price of letterpress printing is often quoted per unit, versus by quantity. Therefore, it is a more feasible technique for print projects with very low quantities.

See the image below of a letterpress business card project we worked on earlier this year.

Modern Deboss Printing

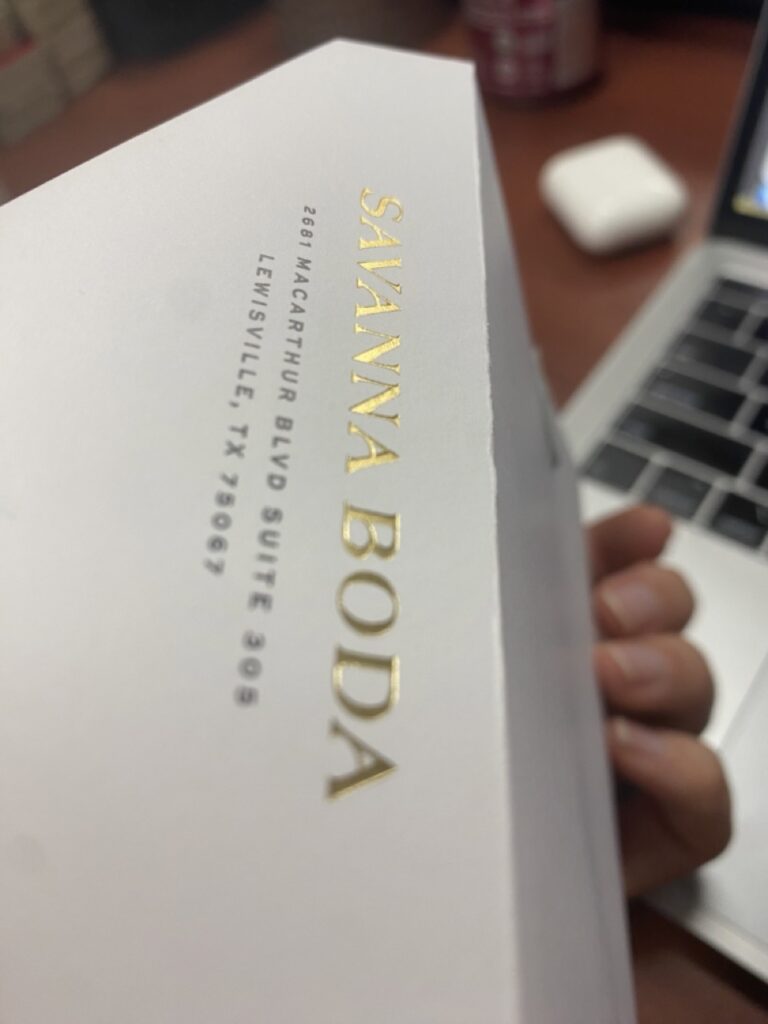

Unlike in letterpress printing, plates used in debossing are typically metal and are printed on modern machines. Because of this, debossing tends to yield a crisper relief and can be done on more types of paper stock, including lightweight paper stocks. Debossing can also yield a reverse relief on the backside of the paper (but this can be avoided), which may add to the overall look of a specific project.

Deboss printing is often a better choice cost-wise if you are planning to print large quantities. This is because as the quantity of a project increases, the individual unit price decreases. Most print done on modern equipment is quoted this way due to the time spent setting up the printer vs. the time spent actually running the print. In other words, small jobs are not worth setting up the printer for and therefore cost more per unit or are not feasible at all.

See the image below of a debossed foil-stamped print project we worked on last year, done on a very lightweight stock.

With a clear comparison between letterpress printing vs. debossing, you can more easily make a decision for your own print project. As always, please don’t hesitate to ask questions regarding your specific needs and unique print project — whether that be via email or in the comments below!

I look forward to helping you bring your next print project to life.